grid | Xtreme VR

High Performance Pure Lead Batteries for UPS, Data Center and Telecommunication

*in comparison to Standard-AGM-Batteries

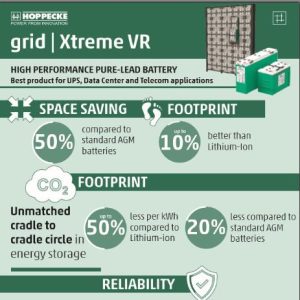

50%*

Saving

20%*

per KWh

2x*

Lifespan

99%*

efficiency

*in comparison to Standard-AGM-Batteries

USE CASE

grid | Xtreme VR -Backing for

international sporting events ►

USE CASE

grid | Xtreme VR -Deployment in Canada's largest nuclear power plant ►

grid | Xtreme VR - even more benefits?

grid | Xtreme VR - even more benefits?

FAQ

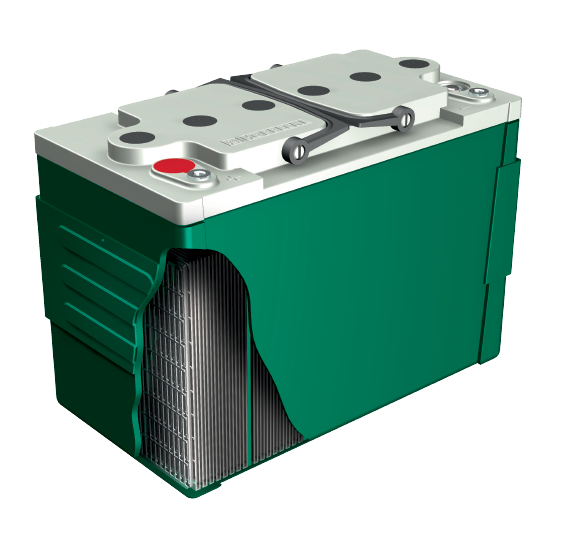

The HOPPECKE grid | Xtreme VR is the next generation of pure lead AGM batteries.

The special design of the grid | Xtreme VR with its thin-plate technology provides superior energy and power density – this means more usable energy in the same installation space. The result is a smaller footprint, which also translates into lower infrastructure costs.

The use of pure lead to produce the electrodes forms the basis of this thin-plate technology. Its superior corrosion properties compared to other lead alloys enable this significant reduction in electrode thickness with the longer service life at the same time.

In addition, pure lead increases stability at high temperatures by reducing electrolyte ageing. This often makes it possible to dispense with air conditioning and thus save energy and CO2 emissions.

The grid | Xtreme VR technology enables use in harsh environments with unreliable power grid.

Short bridging times with high discharge rates are essential requirements in data centers and are supported by the top terminal solution. High energy densities combined with good cycle ability in the compact design of a front terminal battery are fundamental criteria for a secure power supply in telecom applications.

The colour green stands for sustainability and a small CO2 footprint. Lead can be recycled indefinitely in an environmentally friendly as well as efficient way. Here is an example: perhaps the lead from your telecom battery has already been used in your grandfather’s car – that is a cool second life, isn’t it?

The HOPPECKE return and recycling system for lead batteries makes a substantial contribution towards protecting natural resources. In accordance with the “cradle to cradle approach”, HOPPECKE carries out a consistent recycling management. Precious resources are not wasted but reused.

The lead is professionally processed and recycled in the company’s own metal smelter. The recovered metallic lead is refined, alloyed and cast into ingots, which are then fed back into the production process. In this way we ensure careful handling of a scarce raw material, nearly 100% of which is utilised in an environmentally compatible economic cycle.

- Flexible due to up to 24 months shelf life

- Xtremely wide usable temperature range from -40°C to 55°C

- Parallel battery strings for easy scalability of performance

- Stable and safe performance until the end of life

- Safe and easy impedance measurement to determine battery condition

- High serviceability due to true-front terminal connections

It represents the next generation of modern pure lead batteries with the following product benefits:

- Monitored, automated and fully digitalised production processes.

- Complete traceability of every production step

- Long storage time enables high logistical flexibility.

- Uniformity and modularity enable the replacement of expensive individual cells with standardised block batteries.

- Common parts strategy: One model fits all due to parallel battery strings which minimises logistics costs and increases availability.

- Unique dual-pole design enables simple and safe impedance measurements to be carried out using separate measuring contacts on interconnected block batteries.

- Integrated true front connectors for easy installation and safe maintenance.

- Proven ESS technology provides improved recharge, increases resistance to thermal runaway and improves safety and durability.

Several factors influence the service life of a battery: temperature, cycling and temporary overload. It is therefore important to consider these factors to achieve the maximum service life.

Temperature: The use of pure lead with its superior corrosion properties as well as the lower water consumption extends the service life, especially at high temperatures.

Cycles: The EES technology and the lower charge factor of pure lead result in a higher number of cycles and lower energy consumption at the same time.

Temporary overload: The pure lead reduces the wear of the important components of the battery such as the electrode and electrolyte. In detail, this means that both grid corrosion and water consumption are reduced.

As a rule, the weakest link in the chain determines the overall performance. Due to the fully automated production, all components behave evenly which is beneficial to the overall performance of the system and the service life.

HOPPECKE, as a long-term manufacturer of batteries, holds all relevant ISO certificates according to quality. Furthermore, all our products meet the international battery test standard IEC-60896. Additionally, we follow many customer and country specific approvals in telecom, UPS, and railway infrastructure business.

Our grid | Xtreme VR can operate in higher temperature environments, which means less cooling and significant operating cost savings. With its high quality and very long lifetime expectancy it will definitively reduce battery replacement frequency. In addition to this, one model fits all due to parallel strings. This results in minimised logistic cost and increases high availability. So the best of both worlds: low TCO and low OPEX imply optimal total cost!

Available now for orders – take the benefits.

Our grid | Xtreme VR can be operated in higher temperature environments thanks to the extended operating temperature range. This means significant operating cost savings due to less air conditioning. The high quality and very long service life expectancy reduces OPEX, as the batteries need to be replaced less frequently. Thanks to parallel battery strings, the grid | Xtreme VR pure lead battery is also optimally suited for high power requirements. Logistics costs are minimised and availability is increased.

It is the best of both worlds: low TCO and OPEX mean optimal total costs!

You want to know more about the innovative pure lead technology?

The use of the pure lead to manufacture the electrodes forms the basis of the new high-performance pure lead (HPPL) technology. Its superior corrosion properties enable a significant reduction in electrode thickness while simultaneously increasing the service life. The result is a larger electrochemical reaction surface which is pioneering in terms of energy and power density for lead-acid storage technologies.

State-of-the-art simulation software was used to adapt the discharge cross-sections to the increased loads, restricting heat generation to a safe level under all operating conditions. The upper limit of the permitted operating temperature range was increased from 45 °C up to 55 °C. Combined with the dimensionally stable battery case this makes the grid | Xtreme VR particularly suitable for use in harsh environmental conditions.

In addition, HPPL technology also uses active masses with higher density, which were previously only used for deep cycle lead-acid batteries. As a result, the innovative HOPPECKE grid | Xtreme VR combines in one product series properties previously only available in two different product series.

grid | Xtreme VR Top-Terminal in grid | XtremeStack

Energy solution with system

utilize space for

1632 Batteries

1340 batteries

The innovative stacking device grid | XtremeStack in combination with the grid | Xtreme VR in the Top Terminal variant for maximum performance.

►Space-saving, patented system solution with 20 % more batteries in the same space.

►Optimum use of space with up to 27 % less surface area and 22 % higher energy density

►Simple, space-saving and modular design for flexible expandability

Digital Energy World - Discover your potential!

With many years of experience in different fields of application, technologies and good product knowledge we can implement a custom-fit solution with our customers. This reflects our maximum understanding of our customers’ quality requirements. With our expertise, we develop solutions that bring the added value our customers need.

In the digital energy world of HOPPECKE you will find everything you need to unleash the full potential of your business. Our product and service innovations in the field of energy storage have the right solution ready for your every need.

Get ready for a world full of energy and gradually discover more exciting application areas.

HOPPECKE - Energy to move your business ahead!

HOPPECKE is your strategic partner for sustainable and technology-independent energy solutions. If you expect more than just a product but a competent partner who is always at your side, HOPPECKE is the right choice for you.

To tackle the real challenges, we do things differently from the way they are usually done in the market. Our real performance means constantly developing new things as well as enhancing existing ones. In doing so, we develop sustainable energy concepts together with our customers.

A goal that we achieve thanks to the pure lead battery grid | Xtreme VR produced in our new Polish plant. The result of our new site in Poznań is not only a powerful battery for data centers or telecommunication applications, it also takes into account multiple environmental aspects. By building the capacity in Europe, intercontinental sea transports are no longer necessary. In this way, we contribute to reducing environmental pollution and can act faster and more flexibly in Europe. The certification of our plant according to the ISO 9001:2015 and ISO 14001:2015 standards means that you can rely on reliable processes and consistently high quality and environmental standards.